Redefining the first generation multihole saddle design

The first generation multihole saddle design incorporated galvanised tubes, one for each strand, cast in concrete inside a box. This was subsequently refined so that the steel tubes could be omitted, eliminating another potential maintenance issue and allowing the cables to bear directly onto the concrete.

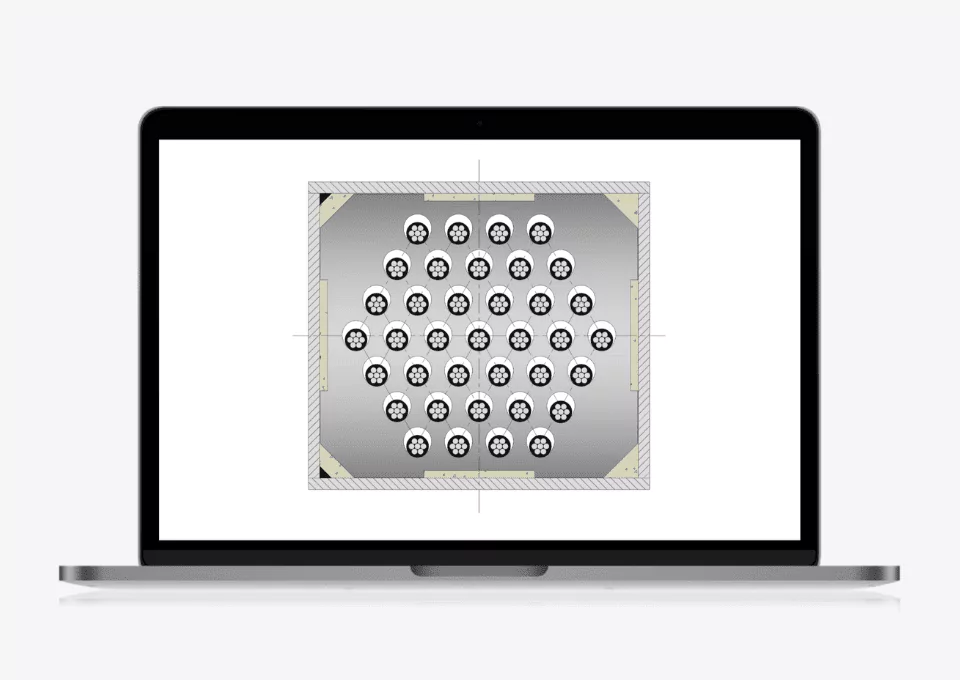

Holes that accommodate each strand have a cross-section in the shape of an inverted water droplet, designed so that under tension, the strand will be pulled into the narrow channel at the bottom of the hole, where it fits snugly. The wider diameter at the top of the void assists with threading of the cables during construction, and subsequent removal if replacement is required.