At the forefront of the bridge construction industry

In 1989, Freyssinet invented the first individually protected multi-strand stay cable, the basis of Freyssinet’s technology for cabled structures. The technique has since been used and improved on more than 300 projects, including the Normandy bridge, the Iroise bridge and the Millau viaduct in France, the Vasco de Gama bridge in Lisbon, the Rion Antirion bridge in Greece, the roof of the BC Place stadium in Vancouver in 2011, and the Russky Island bridge in Vladivostok which, with 1,104-meter main span, still holds the world record.

Today, Freyssinet has developed an ecosystem of expertise in the construction and maintenance of cable-stayed bridges.

-

320+Number of structures worldwide built with Freyssinet stay cables

-

585mWorld record for the length of cable stays with Freyssinet technology (meters)

-

2200Mpa - Highest strand grade used for the Freyssinet cable-stay system

-

100yDesign lifetime of the Freyssinet cable-stay system (years)

Invest in sustainable technology

Cables are the best solution for reducing the weight of bridges while increasing their span, thus saving materials and reducing environmental footprint. They also reduce construction times. These key benefits, along with continued improvements in the technology over the past few years, are why bridge owners are so keen to use them.

With the installation in 2021 of 2160 MPa stay cables on the Saemangeum bridge in South Korea, Freyssinet is showing that innovation is still part of its DNA.

The market benchmark in terms of fatigue resistance, corrosion protection, inspectability and replaceability.

Sustainable technology, constantly optimised in design and implementation to remain at the forefront of the market.

Continuous development of new products and methods to facilitate the integration of stay cables and to make projects successful, even in new configurations.

Our technology is fully qualified to the latest international standards and regularly tested as per:

- fib Bulletin 89 “Acceptance of stay cable system using prestressing steel”, 2019

- PTI DC45.1-18 “Recommendations for stay cable design, testing and installation”, 2018

- CIP “Recommendation of French inter-ministerial commission on prestressing”, 2002

Development of effective solutions thanks to specialist teams networked around the world.

Stay cable systems designed and manufactured under complete control.

Pro-active assistance during the warranty and post-warranty periods, thanks to:

- the strength of the Freyssinet network

- technologies and tools enabling our partners to ensure performance monitoring and preventive maintenance, which are essential for the life of the products and the structure.

A full value chain expertise

Design services

Our design teams develop innovative and customised solutions from pre-engineering to on-site construction. We take on your toughest challenges with the most stringent sustainability criteria.

In-house manufacturing and supply

Freyssinet is one of the few players in the market to integrate the entire supply chain, from engineering and production management to implementation on site.

Integration & installation

The Freyssinet stay cable system has been used on over 300 structures worldwide. The individual installation of the strands and the automatic adjustment by the Isotension® process patented by Freyssinet, allow outstanding flexibility during installation while ensuring the uniformity of the forces in the cables.

Inspection, monitoring, maintenance and replacement services

Representing 5 to 8% of a structure’s investment, cables are critical elements that require regular monitoring. Based on our experience, we have developed a complete range of technical solutions and services for all stages of maintenance of cable-stayed systems.

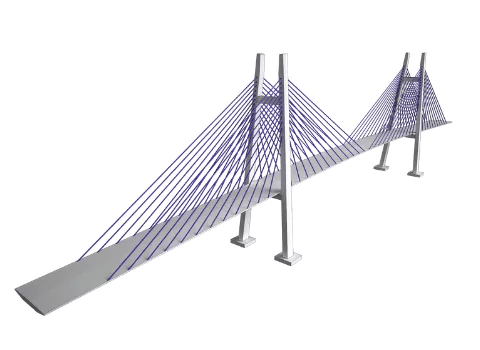

Cable-stayed bridge

- Standard anchorage

- Clevis anchorage

- Multihole saddle

- Built-in saddle

- Monostrand

- Compact Monostrand

- Cohestrand

- CFRP strand (Carbon Fibre Reinforced Polymer)

- Internal Elastomeric Dampers for cables < 80m

- Internal Hydraulic Dampers for cables 80 to 150m

- Internal Radial Dampers for cables 150 to 300m

- External Hydraulic Dampers for cables >300m

- Cross ties

- Fire protection

- Lightning protection

- Ice shedding control

- Blast protection

- Coloured HDPE duct

- Smart LED solution

- Integrated lighting module

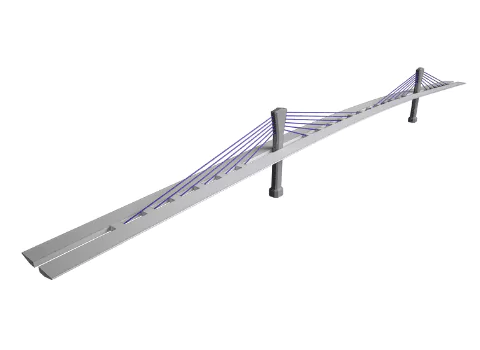

Extradosed bridge

- Extradosed anchorage

- Multihole saddle

- Built-in saddle

- Monostrand

- Cohestrand

- Locally Cohesive Strand (LCS)

- Internal elastomeric dampers

- Fire protection

- Lightning protection

- Ice shedding control

- Blast protection

- Coloured HDPE duct

- Smart LED solution

- Integrated lighting module

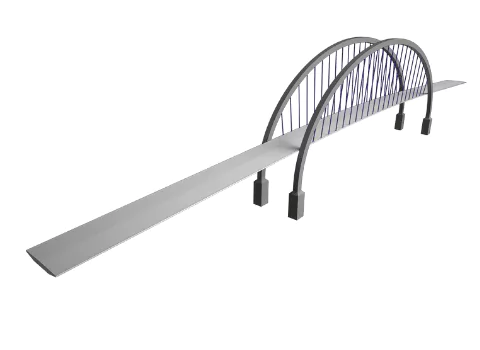

Arch bridge

- Standard anchorage

- Clevis anchorage

- Monostrand

- Compact Monostrand

- CFRP strand (Carbon Fibre Reinforced Polymer)

- Internal elastomeric dampers

- Fire protection

- Lightning protection

- Ice shedding control

- Blast protection

- Coloured HDPE duct

- Smart LED solution

- Integrated lighting module

Suspension bridge

- Standard anchorage

- Clevis anchorage

- Multihole saddle

- Built-in saddle

- Suspension bridge collar

- Monostrand

- Cohestrand

- Suspension hanger

- Fire protection

- Lightning protection

- Ice shedding control

- Blast protection

- Coloured HDPE duct

- Smart LED solution

- Integrated lighting module

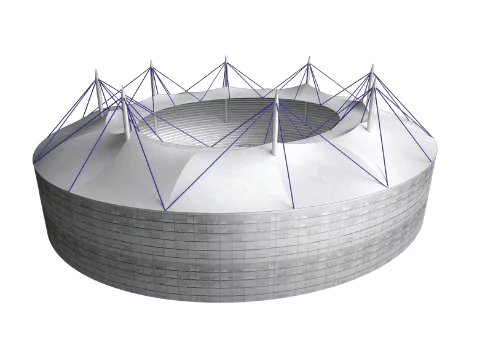

Cabled stadium roof

- Standard anchorage

- Clevis anchorage

- Monostrand

- Fire protection

- Lightning protection

- Ice shedding control

- Blast protection

- Coloured HDPE duct

- Smart LED solution

- Integrated lighting module