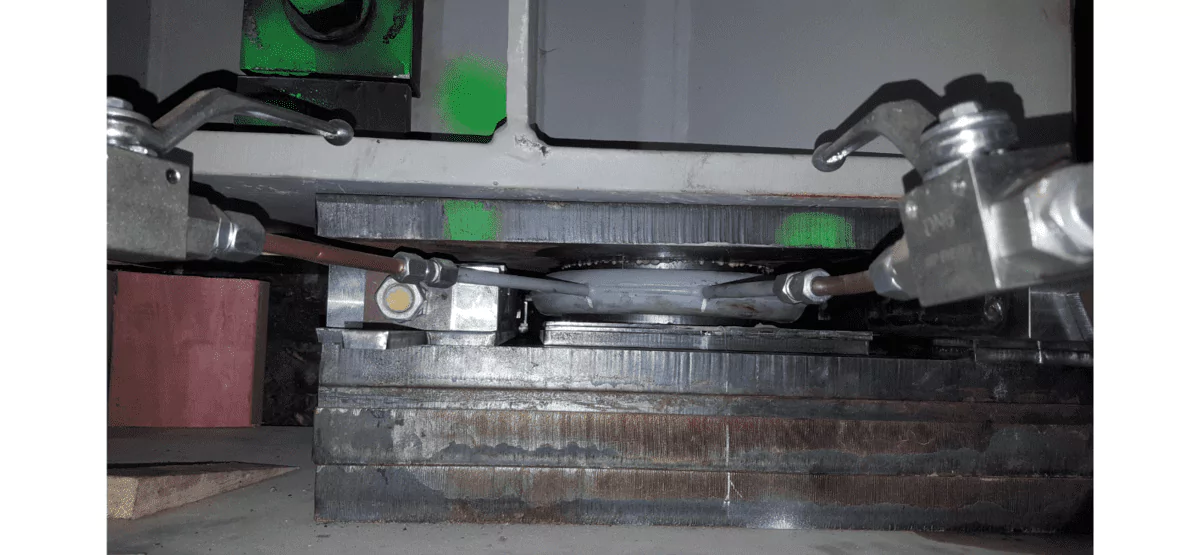

Install post-tensioning to the underpinning beams

The tunnels were formed by installing diaphragm walls along each edge and excavating between them to the required level – a relatively standard procedure under normal conditions. In this case, however, the excavation was to take place directly below an historic building – one whose concrete pad foundations were right above the proposed tunnel routes.

Main contractor Soletanche Bachy carried out the diaphragm wall construction – a tricky operation within the limited physical space of the building.