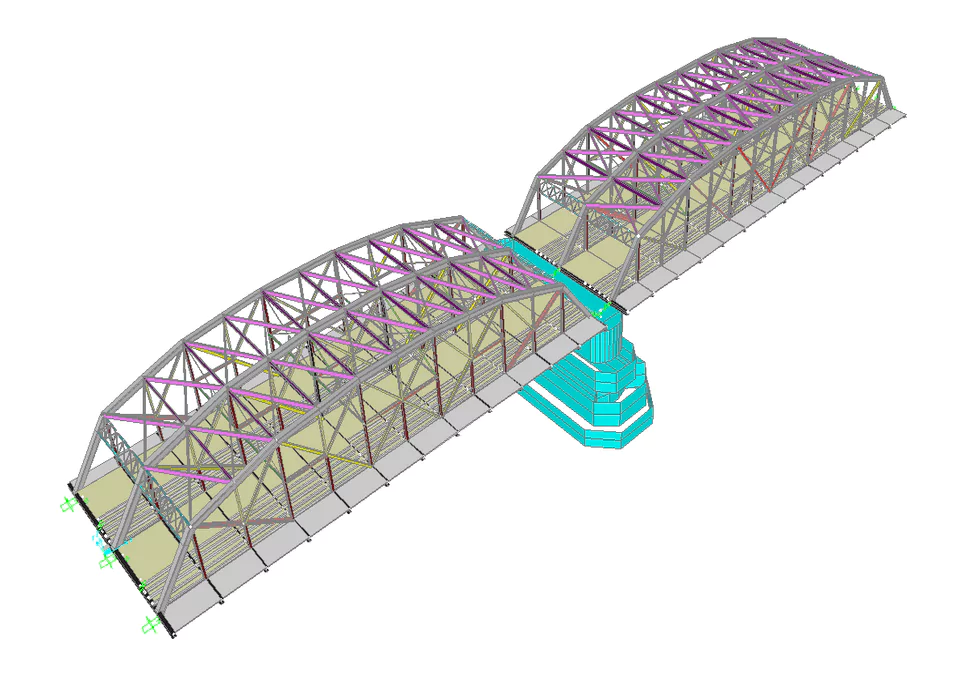

Historical steel bridge upgrading

The two-span truss bridge carries one of the city’s main road arteries over the Pasig River, itself an important transport route for petrochemical tankers and other vessels. Dating from the 1950s, the Ayala Bridge was suffering from corrosion to its steel structure and bearings, and it did not meet modern highway and seismic standards, making it vulnerable to earthquakes. Ships could only pass under the bridge at low tide, so clearance was to be increased by 700 mm to improve access. This was accomplished by raising the entire bridge with strand jacks – a first for the Philippines.