Lightening the load

The bridge owner placed great emphasis on the importance of taking all possible steps to minimise the wind loading – and resulting cable vibration – that the 903 m-long structure would be subjected to.

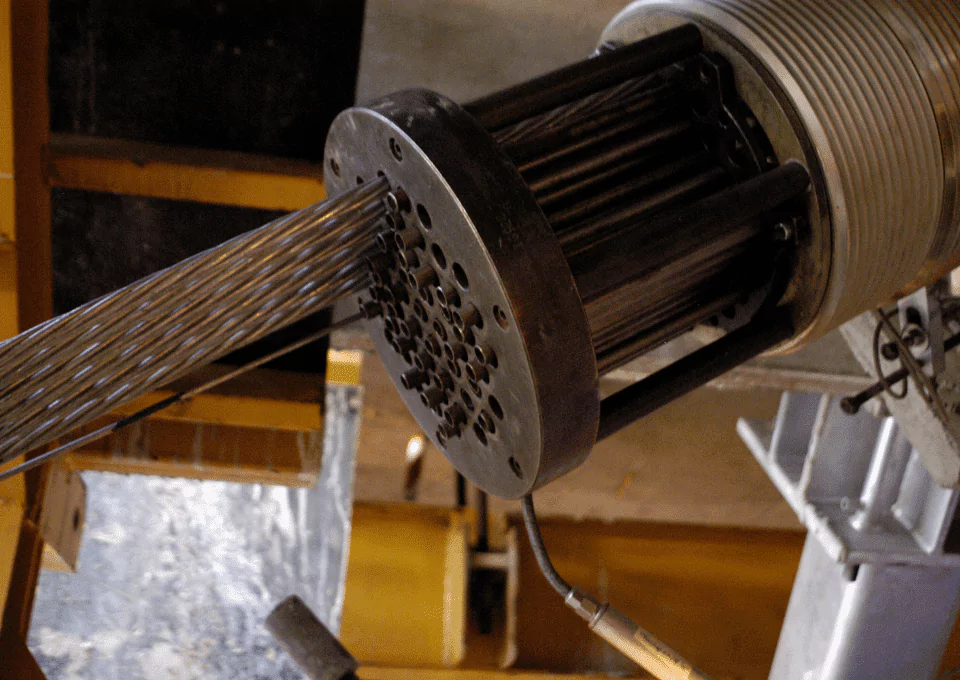

This included specifying the use of compact cables and internal dampers, as well as reducing the profile of the prestressed concrete deck, which with a main span of 435 m was the longest of its type in the world.