Custom structural integrity management system

The silo-management software was designed to enable local operators to carry out a baseline inspection, gathering sufficient information to generate a risk rating for each structure, and if necessary, a priority for further inspection, repair or strengthening. A key task in development of the system was to create a database of all the different types of silo that are present in CRH plants, along with examples of typical structural problems encountered in each.

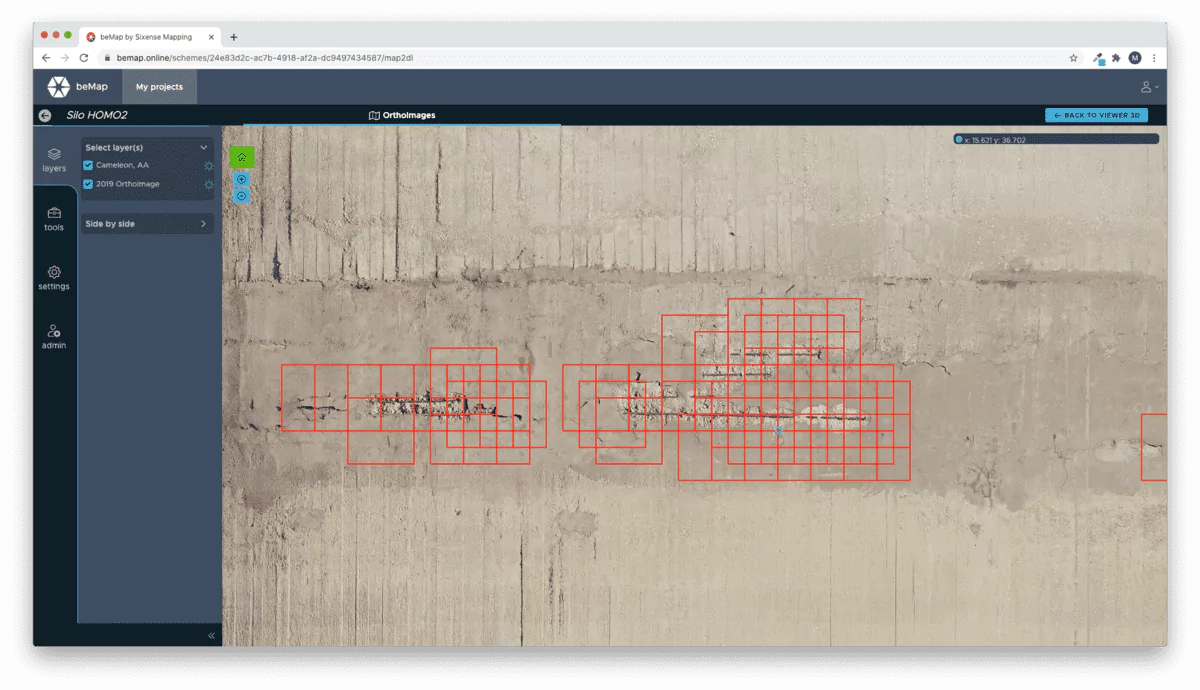

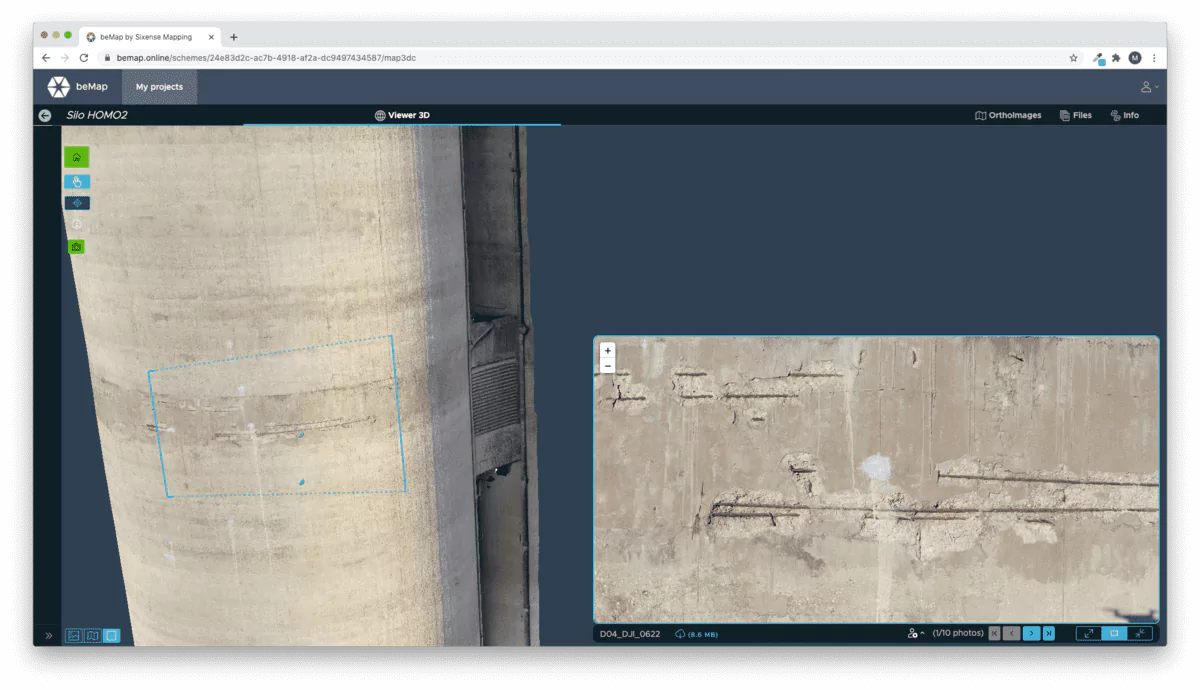

Staff carrying out the baseline inspections do not need specialist knowledge; the system prompts them to record the size and position of any cracks, spalling, corrosion and so on, and upload photos. Once complete, it draws on the database to analyse the structure and give an overview of its condition. If it is currently being used at a restricted capacity, the analysis tool assesses what repairs are needed to increase this.