Slimming down

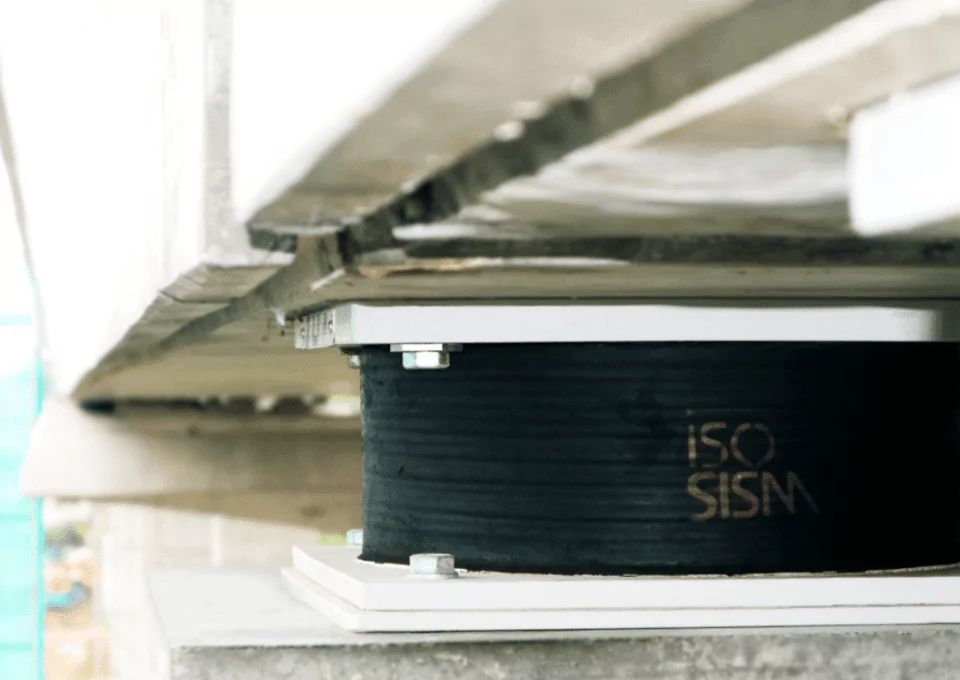

These bearings enable seismic forces to be dissipated without impacting on the structure, hence the design of the piers and piled foundations could be revised to be considerably lighter and slimmer, reducing material quantities and allowing significant savings. Seismic bearing isolators are designed to be flexible during an earthquake event in order to isolate the structure. This isolation effect is represented by significant structural period shifting, reducing the earthquake impact by up to a half. In addition, the bearings have a lead core surrounded by a natural rubber compound and are capable of dampening the response of the structure by up to 29 %.

With a tight construction programme and the start of the 2018 Asian Games as a deadline, it was essential that construction was rapid and efficient. The contractor attached the bearings to the underside of the precast concrete full-span deck units before they were lifted into place, eliminating the need to work at height on the pier tops, or use temporary bearings.