Ship shaped

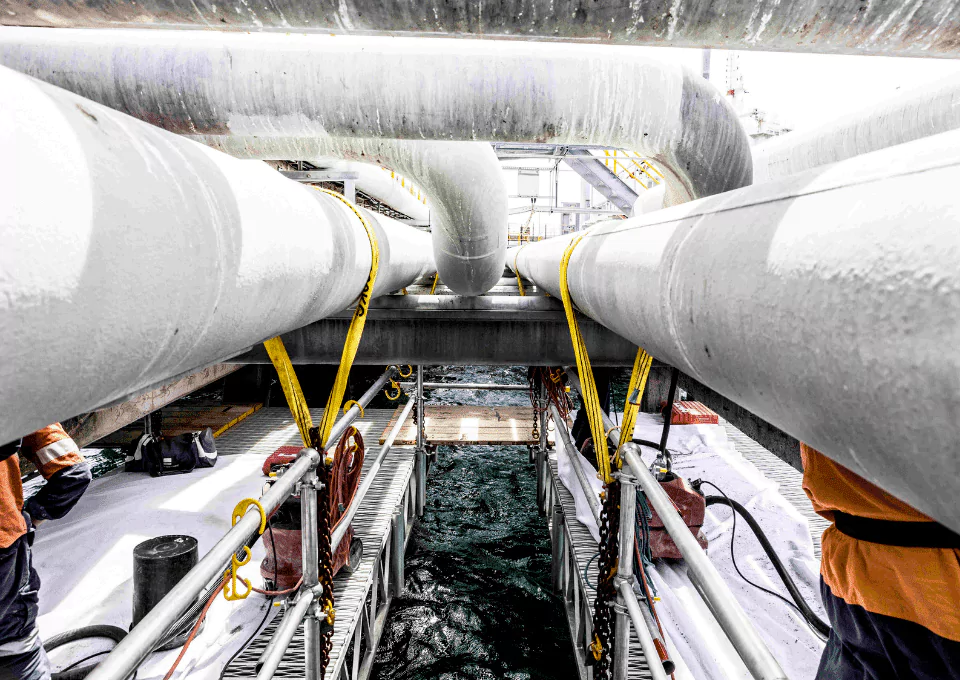

The 1.1 km-long wharf extends to a berthing arm in the bay which has space for two ships – one on each side – to moor up and unload deliveries of diesel or jet fuel to the terminal via the pipes on the structure.

Its simple construction – formed of reinforced concrete beams and deck atop a series of piled bents – belies the complexity of the repair project, which is directly affected by the presence of the moorings. When occupied by ships the berths are classified as hazardous, severely restricting the type of work that can be carried out in the vicinity.