A result of multiple reinforcement strategies

The concrete girder bridge was built in the 1970s and had subsequently been reinforced by the addition of external post-tensioning in order to accommodate heavier loads. But lack of maintenance since that time led to the failure of post-tensioning tendons and prompted the need for the repairs.

The original four-span bridge is 140 m long with each 35 m-long span formed of two concrete beams and a slab. Ten years ago it was widened by the addition of a second structure built using AASHTO beams; the strengthening work was only applied to the original structure.

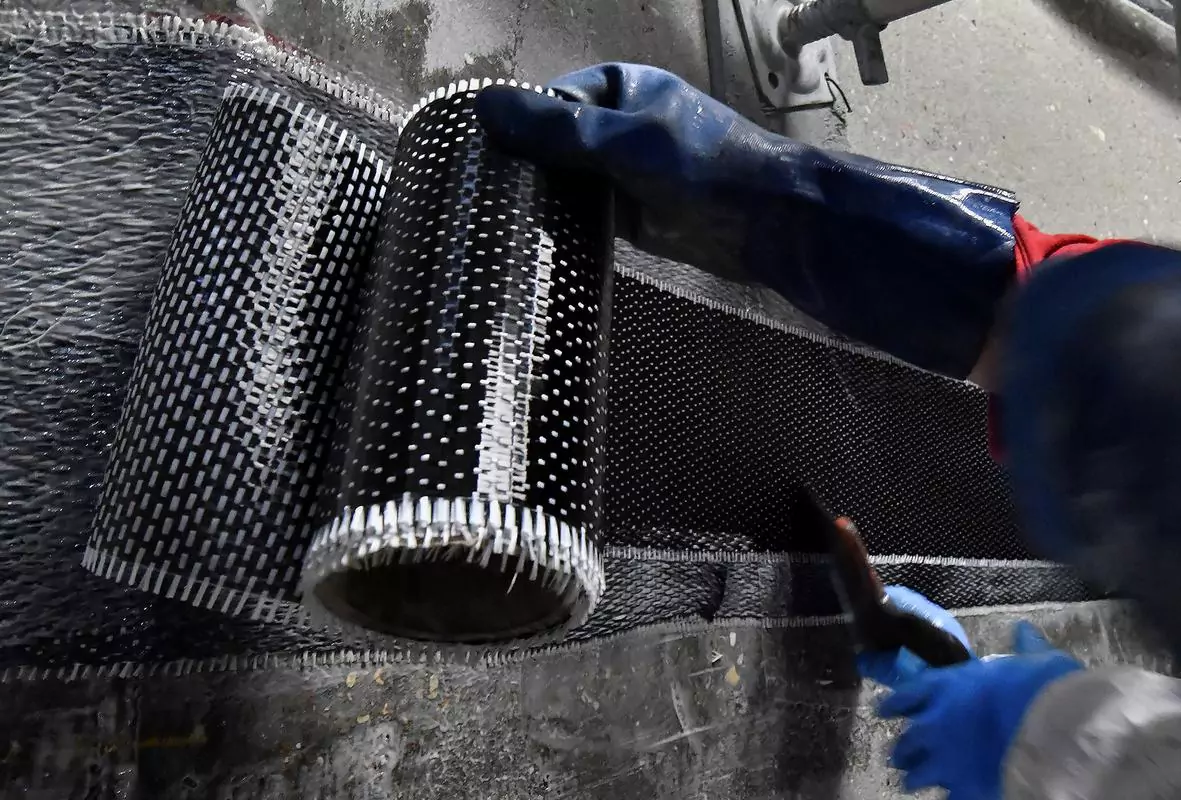

Carbon fibre reinforcement using Foreva TFC 1100

These days, it is common practice to use carbon fibre laminates, or fibre-reinforced fabric applied with epoxy resin to repair or strengthen concrete structures. But this project marked one of the first applications of a high-strength version of Freyssinet’s Foreva TFC, which reduced the number of layers needed and could be applied by ‘dry’ lay up using a single type of resin.

Nothing that the time available for the strengthening work was just a matter of weeks, Freyssinet put forward its Foreva TFC1100 fabric as an alternative to the rigid laminate strips that had been specified. Not only was it quicker to apply, but it required fewer layers of fabric, could be applied ‘dry’, and could accommodate a certain level of roughness on the concrete surface. Laminates would have needed more thorough surface preparation in order to create a smooth surface to eliminate air bubbles and enable an effective bond to be made.

On La Canada Bridge the fabric was applied in up to three layers to the underside of the beams to provide the required reinforcement according to the variable loads across the span. Single-layer strips on the sides of each end of the beams were sufficient to provide the necessary improvement to shear strength.

The site team had to work 12 hours a day, seven days a week to meet the completion date; two weeks to prepare the surface for the application, and the same amount of time to apply the full 2,650 m of fabric.