Restore watertightness and improve hydraulic efficiency

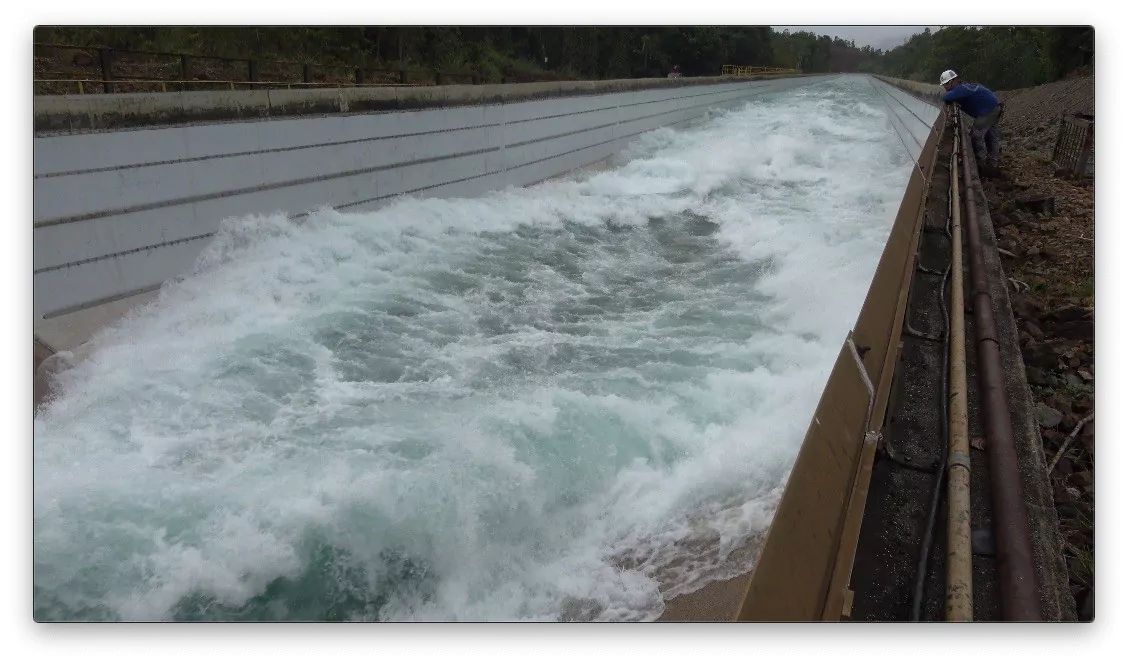

The Larona head pond in Indonesia, located at the downstream end of a 6.7 km long hydroelectric canal, is a storage reservoir for turbine start-up and automatic overload shutdown. Most of the time, the plant is operated at full capacity to generate as much power as possible for a major mining company.

The main objectives of the waterproofing project were to stop leaks to prevent loss of structural integrity, to increase water flow, and to install the waterproofing solution within the 10 weeks of planned shutdown. The solution must also be able to withstand seismic events, as Larona is located in a seismic zone.