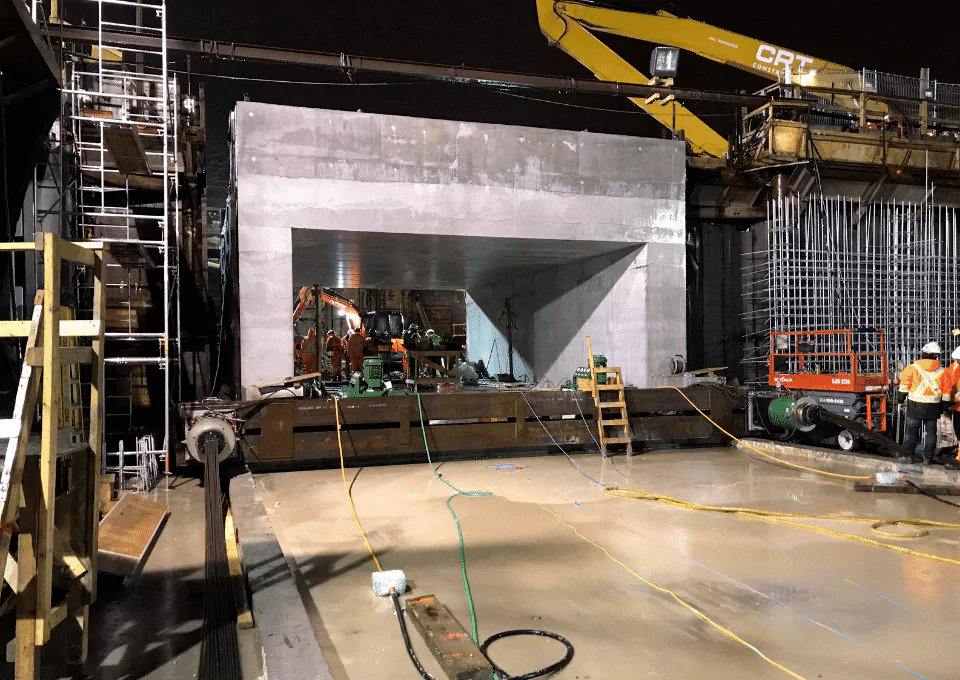

Details of the sliding operation

A sliding slab with side upstands, cast between the structure and the tracks to be crossed, ensures the guidance. The movement is carried out by 1,000 t pushing jacks developed by our Swiss subsidiary HEBETEC. Attached to the ends of a horizontal distribution girder resting on the back of the frame, they act on two cable lines anchored to the end of the slab to gradually tow the structure. To reduce friction, a bentonite-based lubricating grout is injected under pressure below the foundation slab. Thanks to its front edge in the shape of a ski shovel, it slides towards its target, first on the guide slab and then directly on the ground around the track beds. The use of a general raft foundation enables a very good load distribution with an average pressure that does not exceed that of a shoe sole, making the technique applicable to many terrains.