In situ deck construction

Incremental launching

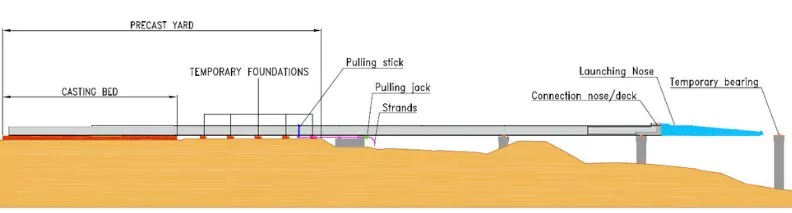

Segments of comparable length are concreted in a formwork or assembled in an assembly area. Then, each segment is match-cast against the previous one and prestressed to the section of the deck already built. As segments are added and slided over special bearings, the increasing length of bridge deck is repeatedly pushed / pulled out of the formwork or assembly area, over the abutment onto the piers, to reach its final position. Provision of a launching nose stressed against the first deck segment will reduce the big bending moments in the deck during launching.

-

Erection rate

one segment every 7 or 8 days -

Quality of segment fabrication

with a sheltered casting yard -

Limited investment in special equipment

(launching nose, jacking system,

launch bearings, side guides)

Incremental launching

Segments of comparable length are concreted in a formwork or assembled in an assembly area. Then, each segment is match-cast against the previous one and prestressed to the section of the deck already built. As segments are added and slided over special bearings, the increasing length of bridge deck is repeatedly pushed / pulled out of the formwork or assembly area, over the abutment onto the piers, to reach its final position. Provision of a launching nose stressed against the first deck segment will reduce the big bending moments in the deck during launching.

-

Erection rate

one segment every 7 or 8 days -

Quality of segment fabrication

with a sheltered casting yard -

Limited investment in special equipment

(launching nose, jacking system,

launch bearings, side guides)

Incremental launching sketch

Cast-in-place cantilever with form travellers

This method is ideally suited: to cross high gaps and avoid ground constraints for bridges whose length does not require prefabrication, or with different cross sections or casting lengths

-

High erection rate

one pair of segments every 3 to 7 days -

Long-span bridges

with access constraints -

Limited investment

Cast-in-place cantilever with form travellers

This method is ideally suited: to cross high gaps and avoid ground constraints for bridges whose length does not require prefabrication, or with different cross sections or casting lengths

-

High erection rate

one pair of segments every 3 to 7 days -

Long-span bridges

with access constraints -

Limited investment

Our references in deck construction

Contact us

You have a question about our solutions or you already have a project in mind? Please fill out the form below and our teams will get back to you shortly.