A simple and robust design

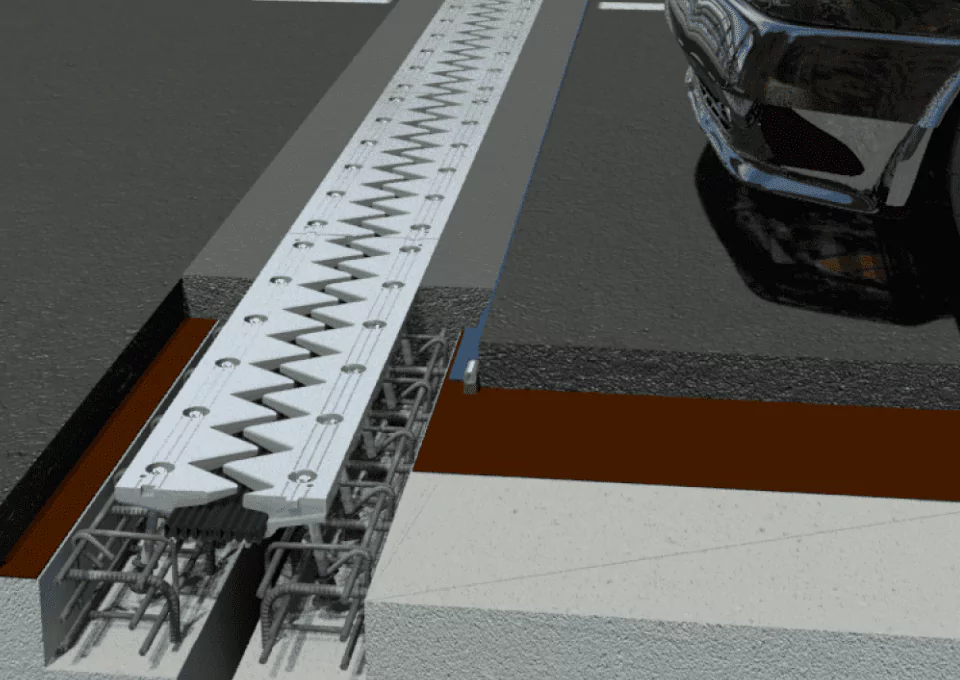

- Aluminium alloy or steel elements that ensure the strength of the joint. Short modules facilitate installation under traffic as well as maintenance and cleaning.

- Anchoring systems that connect the joint to the main structure.

- Continuous elastomeric elements inserted along the entire length of the expansion joint between the metal elements, to prevent the penetration of foreign bodies and to collect run-off water.

Our expansion joints comply with all main standards worldwide.