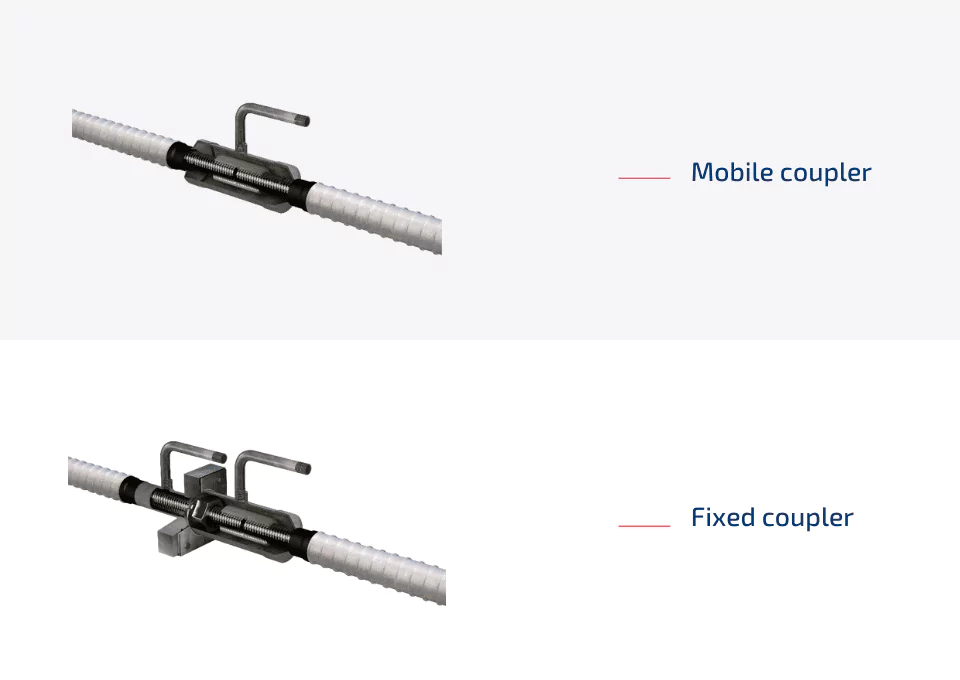

Couplers

Mobile couplers are used to connect two bars together on their main run. The duct is adapted by the coupler to provide unhindered movement during tensioning.

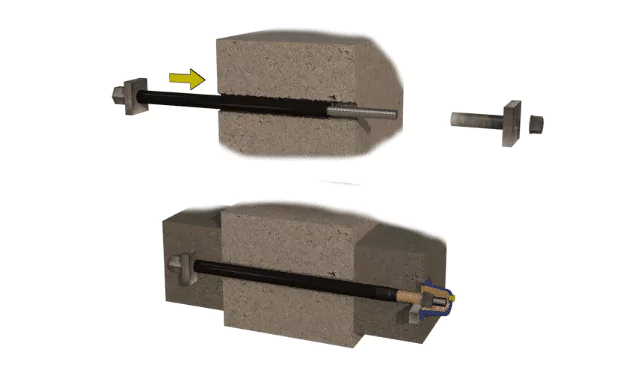

A fixed coupler is used to extend a prestressing unit already under tension by screwing a coupler to the end of the bar protruding from the anchor. In this case, the coupler barely moves during tensioning. A special cap is used to ensure a continuous duct.