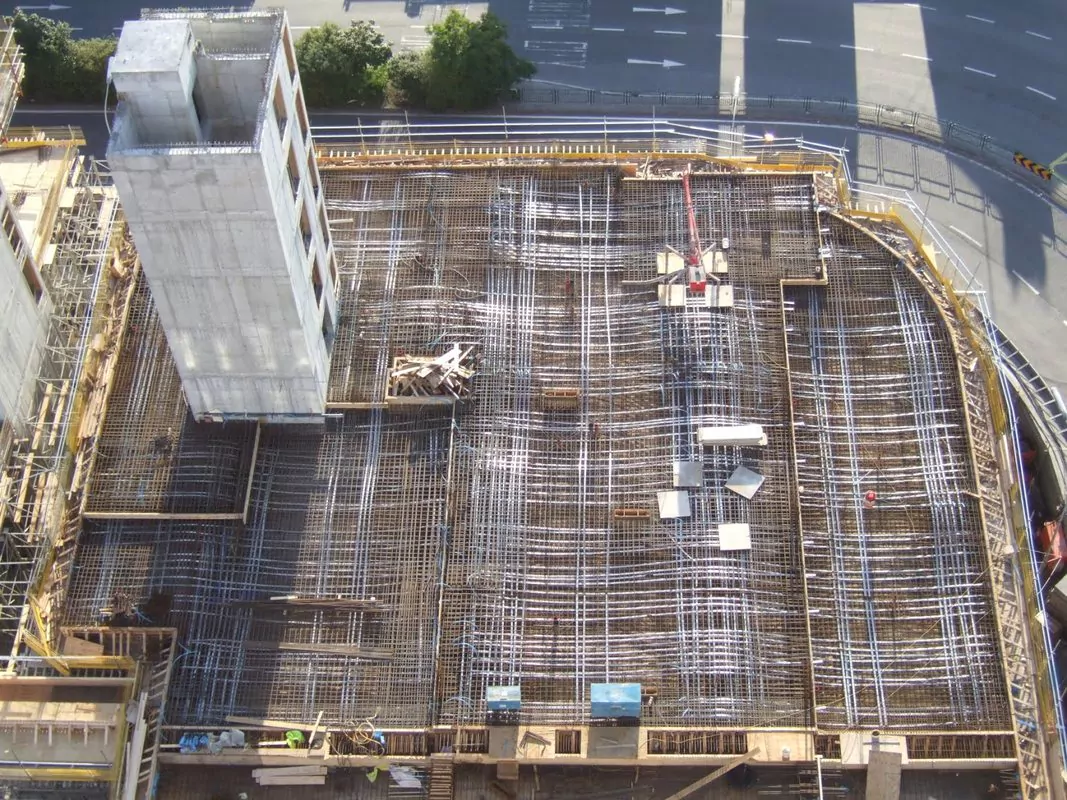

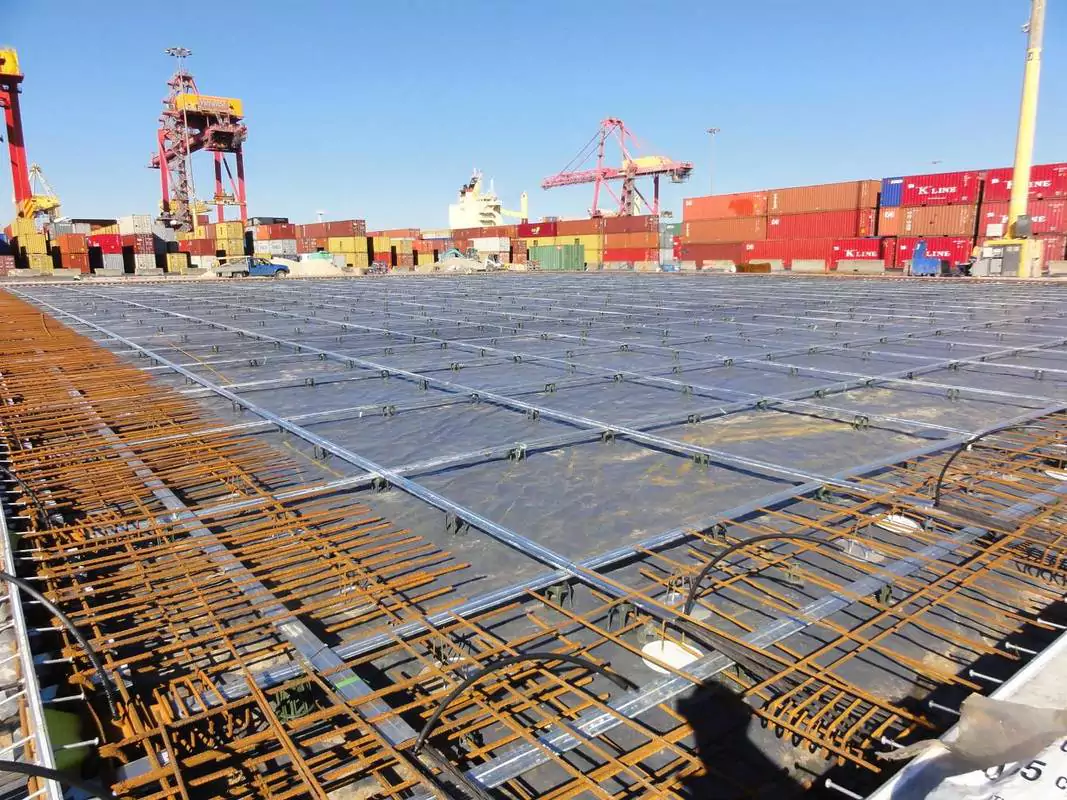

Building floors

Freyssinet’s post-tensioning systems can be used in the construction of the floor slabs for a wide range of building types:

- Residential buildings

- High-rise office buildings

- Shopping centres

- Underground / traditional Multi-Storey Car Parks (MSCP)

- Public facilities – hospitals / schools / sports halls

Many of the previously described benefits can be achieved for the benefit of architects, owners and contractors alike, particularly for buildings with large plan dimensions or for high rise structures.