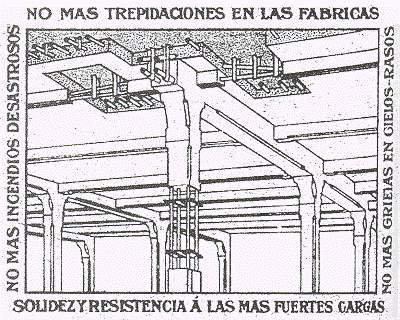

One of the few surviving examples of the Hennebique system

This solution derives its name from French engineer François Hennebique (1842–1921), who is considered to be the father of reinforced concrete. The system features a simple arrangement of columns and ribbed floor slabs (main beams, trusses and slabs) made from reinforced concrete. The major innovation was that the longitudinal reinforcements were joined vertically by a series of abutments to provide structural support, and arranged closer together as they approached the bearings.

The CACI plant fell into disuse in the 1980s, but was taken over by the city’s authorities, who decided to refurbish the site as part of their plans to open the Catalan Museum of Comics and Illustration. Freyssinet was awarded the contract for the first phase of carrying out the structural refurbishment works.