Lateral sliding / Lennetal Highway Bridge, Germany

It took less than 6 hours to move the 30,000 ton, 1,000-metre-long Bridge by 19.15 meters sideways in its final position.

These operations can be performed at ground level on a short distance, and at heights, when heavy structures are shifted to their final position or when heavy loads are removed from their current position. These methods apply to new build projects, structure dismantling or when replacing part of an existing structure.

Lateral sliding / Lennetal Highway Bridge, Germany

It took less than 6 hours to move the 30,000 ton, 1,000-metre-long Bridge by 19.15 meters sideways in its final position.

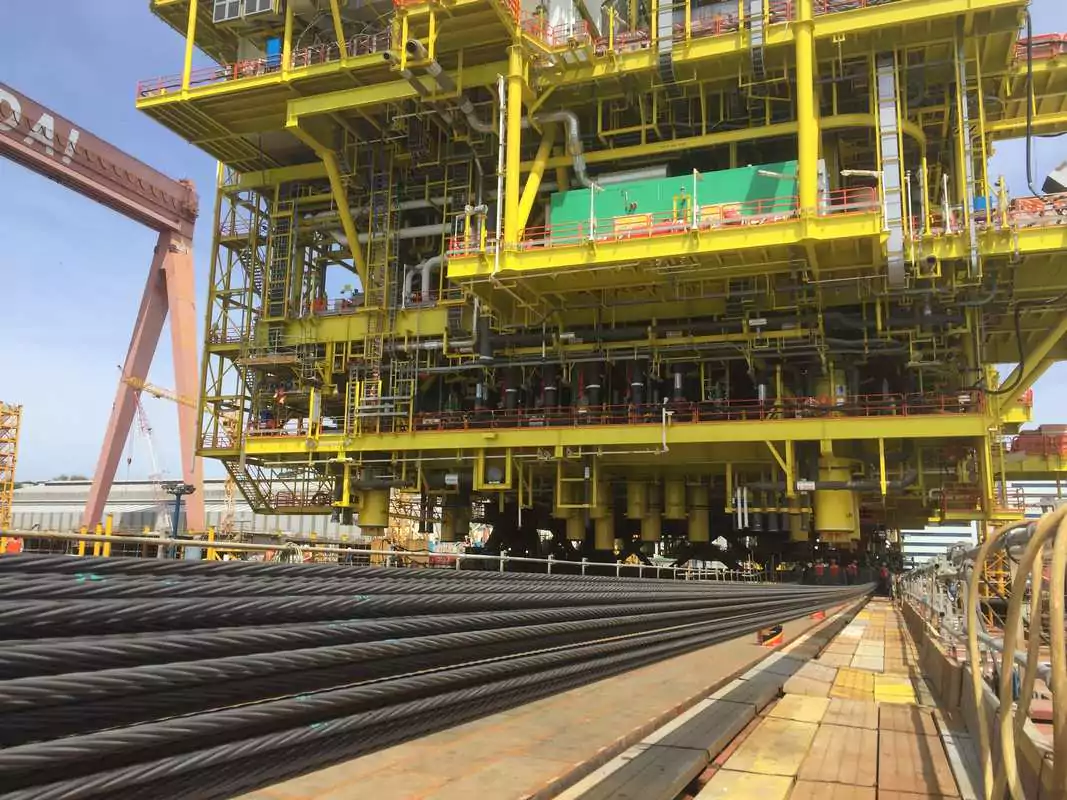

Load out / Oil Rig Baronia at Ulsan, Korea

17’000 ton weighing oil rig was shifted to load on bord of a barge and eventually put into operation in the Gulf of Thailand

Combined APS sliding & heavy lifting operations / Ashalim Solar Power Station, Israel

APS sliding of a 2,300t. boiler on 64 m from the assembly area to the power station tower

Bridge launching / Bowstring bridge, Casablanca, Morocco

The 330-ton steel structure of the Bowstring Bridge was launched over the A3 city highway crossing. The operation took place overnight, resulting in a short traffic closure and minimal disruption as the arch bridge was pre-assembled next to the roadway.

You have a question about our solutions or you already have a project in mind? Please fill out the form below and our teams will get back to you shortly.