One of the most important move in this area is the development of the Monostrand technology -for individually protected strands, that was carried out by Freyssinet at the end of the eighties and installed on a few bridges as soon as 1988. The objective was to get a protection that is durable, flexible enough to accommodate deformation and elongations and that can connect to the anchorage in a proper way.

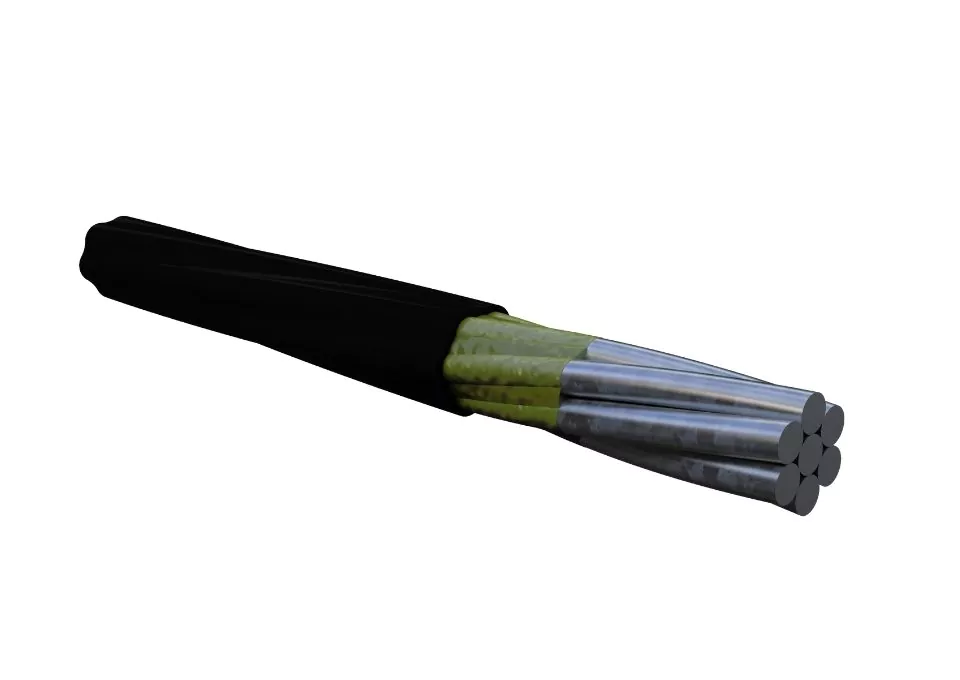

Several years of R&D lead to the industrial development of the wax and HDPE (High Density Polyethylene) sheathed semi-bonded mono-strand for which the sheathing is semi-bonded to the steel strands thanks to a qualified amount of wax. The HDPE sheathing is tight enough on the strand so that thermal expansion is the same for both materials.