As a new feature, all Freyssinet spherical bearings are now using ISOGLIDE® material instead of pure PTFE.

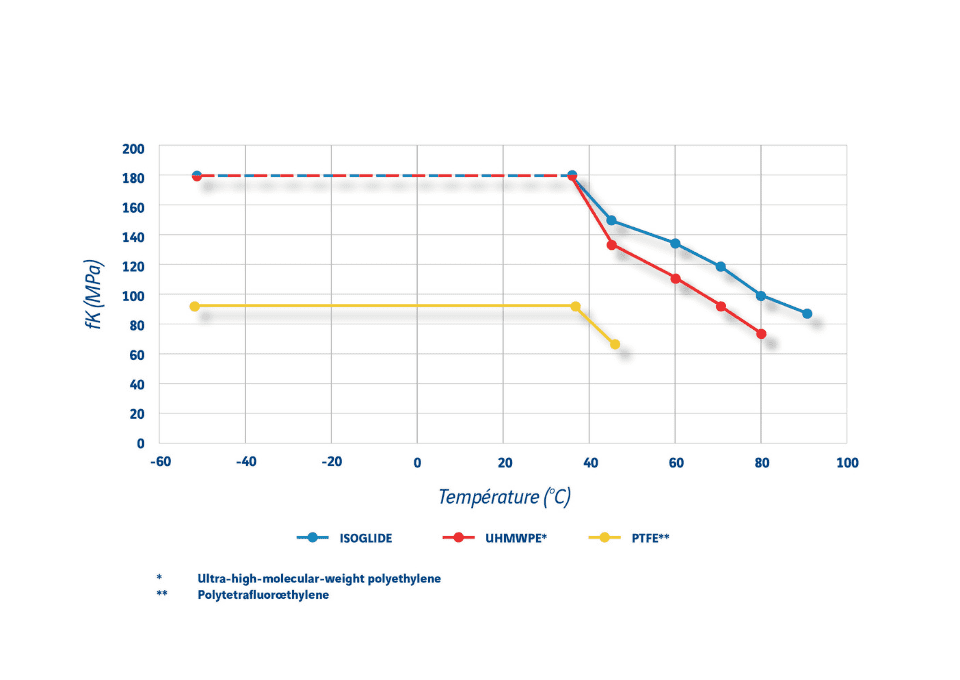

- ISOGLIDE® accepts higher stresses than PTFE (compression strength of 180 N/mm2), which in most cases makes it possible to reduce the dimensions of the bearing.

- Friction factor <2% in a moderate temperature range

- Friction factor <3,5% at very low temperatures

- It is also five times more resistant to wear than PTFE (up to 50 km), which is particularly interesting for uses involving frequent and repetitive movements and rotation. It allows extended service life with reduced maintenance costs.

Last but not least, it is resistant to extreme temperatures, from -50°C to 90°C.